Preserving your homegrown harvest or favorite recipes for later enjoyment is a rewarding experience. Water bath canning is a safe and effective method for preserving low-acid foods, ensuring their quality and extending their shelf life. This guide will walk you through the essential steps, from preparing your equipment and food to processing and storing your creations, ensuring a successful and enjoyable canning experience.

This comprehensive guide delves into the practical aspects of water bath canning, covering everything from selecting the right equipment to understanding crucial safety procedures. We’ll explore the history of this time-tested method, the specific types of foods suitable for this technique, and detailed procedures to ensure safe and successful results. Whether you’re a novice or an experienced home cook, this guide will provide you with the knowledge and confidence to embark on your canning journey.

Introduction to Water Bath Canning

Water bath canning is a safe and effective method for preserving low-acid foods, such as vegetables and fruits, for extended periods. It involves heating food in a water bath to achieve a specific temperature and time needed to eliminate harmful bacteria and prevent spoilage. This process is particularly crucial for foods that don’t naturally contain enough acidity to prevent bacterial growth on their own.

Proper canning techniques are essential to ensure food safety and maintain the quality of the preserved food.Understanding the importance of safety procedures is paramount. Following established guidelines is critical to avoid foodborne illnesses and ensure that the preserved food is safe for consumption. Incorrect canning methods can lead to the growth of harmful microorganisms, which can result in illness.

This is why adhering to the precise instructions and guidelines for water bath canning is of utmost significance.

History of Water Bath Canning

The development of water bath canning techniques was a significant advancement in food preservation. Early methods focused on boiling food to kill bacteria, but water bath canning refined the process, providing a consistent and effective method for preserving a wide range of foods. The technique’s evolution reflects continuous improvements in understanding food safety and the factors influencing bacterial growth.

Over time, standardization of procedures and equipment has further enhanced the safety and reliability of this method.

Types of Food Suitable for Water Bath Canning

This method is ideal for low-acid foods. This category includes vegetables like beans, carrots, and peas; fruits like pears and peaches (when properly prepared); and certain types of jams. A critical aspect is understanding the specific guidelines for each type of food, as different foods may require adjustments to canning times or temperatures based on their acidity levels.

These considerations ensure the safety and quality of the preserved food.

Importance of Safety Procedures

Safe canning practices are essential to prevent foodborne illnesses. Following established guidelines and using the appropriate equipment is crucial. This involves precise temperature control, proper time management, and using jars and lids that are suitable for the canning process. These practices minimize the risk of contamination and ensure the preservation of the food’s quality and safety. The use of a thermometer is critical to ensuring that the water reaches the correct temperature for a specific time.

Understanding the Importance of Water Temperature

The temperature of the water bath is a critical factor in the effectiveness of water bath canning. A precise temperature ensures the complete destruction of harmful microorganisms. The specific temperature requirements depend on the type of food being canned. Using a thermometer to monitor the water temperature is crucial to maintaining the safety and quality of the canned food.

This helps avoid potential issues associated with insufficient heat treatment.

| Food Type | Approximate Temperature (Celsius) |

|---|---|

| Low-Acid Vegetables | 80-100°C |

“Consistent monitoring of water temperature is essential for ensuring the effectiveness of the canning process.”

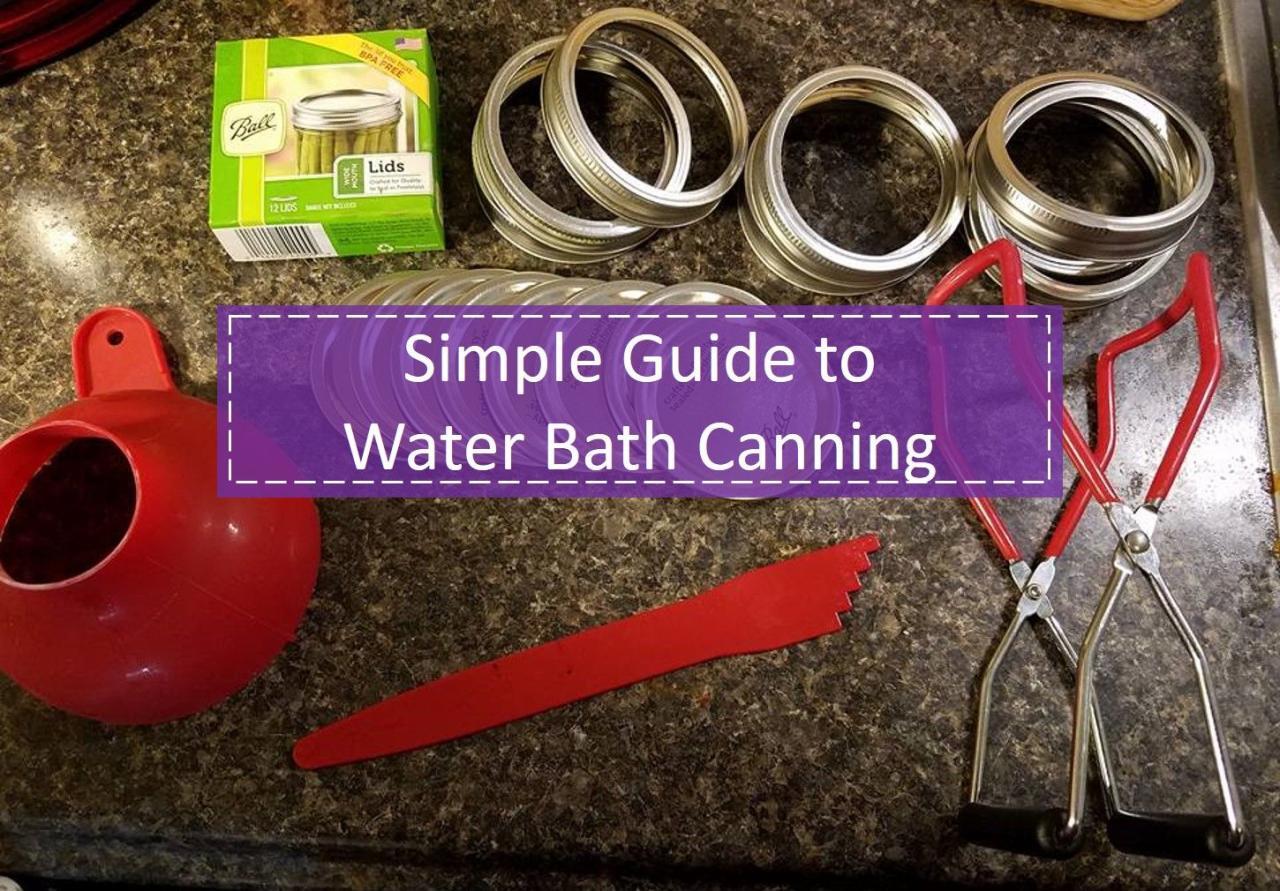

Essential Equipment for Canning

Proper equipment is crucial for successful and safe water bath canning. Selecting the right canner, jars, and accessories ensures food preservation and prevents contamination. Careful consideration of these factors contributes significantly to the quality and safety of your canned goods.Choosing the appropriate equipment and following proper procedures are essential for achieving safe and high-quality canned products. This section details the various types of canners, necessary supplies, and the significance of jar selection.

Types of Water Bath Canners

Understanding the different types of water bath canners available is key to selecting the right one for your needs. Each type offers varying benefits and drawbacks.Different canners cater to diverse needs. The choice depends on factors like the amount of canning you plan to do, available space, and budget. Consider the volume and weight capacities when choosing a canner.

- Standard Canner: This is the most common type, often made of heavy-gauge steel or aluminum. They are generally affordable and effective for smaller batches. A standard canner is a good choice for home cooks who are just starting out with canning. However, they might not be ideal for very large canning projects.

- Electric Canner: These canners use electricity to heat the water, offering a more consistent and controlled temperature. This can lead to better results, especially for large batches, as the temperature doesn’t fluctuate. However, electric canners can be more expensive than standard canners. Electric canners are suitable for those who want a convenient way to heat water for canning, especially when dealing with larger batches.

- Pressure Canner: While not a water bath canner, pressure canners are used for high-acid foods like fruits and vegetables. These canners use steam pressure to reach higher temperatures, making them appropriate for foods that need to be processed at higher temperatures than water bath canning allows. Pressure canners are essential for preserving low-acid foods.

Essential Equipment List

A comprehensive list of equipment ensures smooth and safe canning procedures.

- Water Bath Canner: This is the primary vessel for heating the jars and their contents.

- Mason Jars: Glass jars specifically designed for canning. They are essential for storing food safely. Choose jars that are appropriate for the food you are canning.

- Lids and Rings: These components create a seal to prevent contamination. Always ensure they are in good condition and use a new lid and ring for each jar.

- Jar Lifter: A tool to safely remove jars from the canner without burning your hands. A jar lifter is important for handling hot jars without risk.

- Canning Funnel: A funnel aids in pouring food into jars, minimizing spills.

- Ladle: Used to transfer hot food or water.

- Jar Labels and Markers: For identifying contents and dates.

Jar Selection for Different Foods

The choice of jars directly affects the safety and quality of the canned food.Proper jar selection is critical for preventing spoilage and ensuring the safety of canned foods. Different jars are designed for different food types and quantities. Selecting the correct jar size for your canning needs is important for food safety.

- Pint Jars: Suitable for smaller quantities of food, like fruits, vegetables, or jams. They are a good choice for smaller batches of homemade preserves.

- Quart Jars: Ideal for larger quantities of food, like larger batches of fruits or vegetables.

- Half-Gallon Jars: Used for even larger batches of food.

Canner Size Comparison Table

The appropriate canner size depends on the batch size and the number of jars.

| Canner Size (Gallons) | Suitable Batch Size | Jar Count (Approx.) | Suitability |

|---|---|---|---|

| 6 | Small to Medium | 10-20 | Good for beginners or smaller projects. |

| 8 | Medium to Large | 20-30 | Ideal for larger families or home canning enthusiasts. |

| 10 | Large | 30+ | Suitable for large-scale canning or for multiple batches. |

Preparing Food for Canning

Proper food preparation is crucial for successful water bath canning. Following these steps ensures that your canned goods are safe to eat and maintain their quality. Thorough cleaning and preparation, along with attention to detail, are key to a successful canning experience.Thorough preparation is essential for preventing the growth of harmful bacteria and preserving the quality of your canned food.

Careful handling of ingredients, proper sanitation, and precise techniques all contribute to a safe and enjoyable canning experience.

Washing and Preparing Food

A critical first step is thorough washing and preparing the food items destined for canning. This involves removing any impurities or potential contaminants, ensuring the safety and quality of your finished product. Different foods require different approaches, and specific methods should be followed to maintain the integrity of the ingredients. For example, fruits should be washed and cut to the desired size, while vegetables may require peeling and chopping.

- Fruits: Fruits should be washed thoroughly under cool running water. Any damaged or bruised portions should be removed. Depending on the recipe, fruits may need to be peeled, cored, or chopped. For example, peaches need to be peeled and pitted before canning.

- Vegetables: Vegetables should be washed thoroughly, and any damaged or discolored portions should be trimmed. Vegetables might need to be peeled, chopped, or sliced depending on the specific recipe. For instance, carrots need to be peeled and cut into manageable pieces.

- Meats: Meat products intended for canning require meticulous preparation. All meat must be cooked before being placed into jars. Thoroughly inspect for any signs of contamination. For example, meat should be cooked to an internal temperature that ensures safety and then prepared in a way that is consistent with the recipe.

Removing Air Bubbles

Removing air bubbles is vital for preventing spoilage and maintaining the integrity of the canned food. Air pockets can trap moisture and lead to bacterial growth, and therefore the removal of air bubbles is paramount.Properly removing air bubbles ensures that the food is in contact with the liquid, helping to create a safe and sealed environment that inhibits microbial activity.

- Method: Using a clean utensil, carefully push any air bubbles to the top of the jar. Alternatively, you can use a small spatula to gently push the food down and remove the air pockets. A final check using a clean spoon or spatula should be performed to ensure no air pockets remain.

Filling Jars with Food

Correctly filling jars with food and leaving appropriate headspace is essential for a successful canning process. This ensures that the jars have sufficient space for the food to expand during processing. Appropriate headspace allows for the necessary pressure to be built up, ensuring safety and quality.

- Headspace: Always use a canning jar funnel to facilitate a smooth transfer of food into the jars. Leaving the proper headspace, typically specified in the recipe, is critical for successful canning. For example, recipes often provide detailed instructions on the headspace requirement.

- Filling: Fill the jars according to the recipe, ensuring that the jars are filled to the appropriate level. Do not overfill, as this can lead to issues during processing. After filling the jar, use a clean spatula to ensure that the food is evenly distributed, and gently push down on the food to remove air bubbles.

Common Mistakes to Avoid

Avoiding common mistakes can help ensure successful canning. By paying attention to these pitfalls, you can minimize the risk of contamination and spoilage.

- Overfilling jars: Avoid overfilling jars, as this can lead to a lack of headspace, compromising the seal and increasing the risk of spoilage.

- Insufficient headspace: Leaving insufficient headspace is a critical error. It prevents the necessary pressure from building during processing, compromising the integrity of the seal and increasing the risk of contamination.

- Using damaged jars: Using damaged or cracked jars can result in leakage and contamination. Always check jars for any signs of damage before use.

- Improper washing: Ensure that jars, lids, and rings are properly cleaned before use. Improper washing can introduce contaminants and compromise the safety of your canned food.

The Canning Process

The canning process, a critical step in preserving food, involves carefully assembling the canner, filling it with water, and then safely processing jars of food within a controlled environment. Proper execution ensures the safety and quality of your home-canned goods. Understanding these steps is essential for successful canning and preventing potential foodborne illnesses.

Assembling the Canner and Filling with Water

Before introducing food into the canner, the canner itself needs careful preparation. First, place the canner on a stable surface. Ensure the canner’s rack is securely positioned within the canner pot. This rack will support the jars, preventing them from sitting directly on the bottom and potentially breaking. Next, carefully add water to the canner, filling it to the appropriate level.

This level is critical for maintaining the proper temperature for safe processing. Fill the canner with cold water.

Maintaining the Correct Water Level

The water level in the canner must be maintained at a sufficient depth to fully submerge the jars and maintain the correct temperature for the duration of the processing time. This crucial aspect of the canning process is frequently overlooked, and its importance cannot be overstated. A fluctuating water level can result in inconsistent processing temperatures, compromising the safety of the canned food.

Processing Food in the Water Bath Canner

Proper processing involves several crucial steps, each playing a role in achieving safe preservation. Carefully place the filled jars onto the rack within the canner. Ensure there is adequate headspace in each jar, a critical factor for safety. Adding the lid to the jars is crucial and should be done according to the instructions for the specific jars. Ensure the lids are properly tightened.

Then, carefully lower the rack with the jars into the simmering water. The water level should fully submerge the jars.

Precise Timing and Temperature Maintenance

Precise timing is essential for effective food preservation. The specific processing time for each food type varies depending on factors like the jar size and the altitude of the canning location. Use a reliable thermometer to maintain the correct temperature, ensuring that the water in the canner is consistently at or above the required temperature. The temperature should be monitored and maintained at the specified point for the necessary time.

Deviation from the specified temperature or time could compromise the preservation of the food. Using a reliable timer is also recommended to monitor processing times.

Step-by-Step Procedure for Safely Processing Jars

- Prepare the jars, lids, and rings according to the specific food recipe instructions.

- Fill jars with the prepared food, leaving appropriate headspace.

- Carefully place the filled jars on the canner rack.

- Add cold water to the canner, ensuring the water level covers the jars by at least one inch.

- Bring the water to a gentle boil, ensuring an even boil over the jars.

- Reduce heat to maintain a simmer and process the jars according to the specific recipe’s processing time.

- Remove the canner from the heat and allow the jars to cool naturally in the canner for 12-24 hours. This allows for proper sealing.

- Check the seals of the jars after cooling. A properly sealed jar will have a concave lid.

Processing Times and Temperatures

Proper processing times and temperatures are crucial for ensuring the safety and quality of your canned goods. These parameters are determined by factors like the acidity of the food and the altitude of your canning location. Understanding these parameters is vital for preventing spoilage and foodborne illnesses.

Processing Time and Temperature Chart for Low-Acid Foods

To ensure the safety of your canned low-acid foods, meticulous attention to processing time and temperature is paramount. A properly functioning water bath canner ensures safe preservation.

| Food | Processing Time (minutes) at sea level | Processing Time (minutes) at 1,000 ft altitude | Processing Time (minutes) at 2,000 ft altitude | Processing Temperature (°F) |

|---|---|---|---|---|

| Beans (green or wax) | 45 | 50 | 55 | 212 |

| Corn on the cob | 40 | 45 | 50 | 212 |

| Peppers (sweet) | 40 | 45 | 50 | 212 |

| Carrots | 40 | 45 | 50 | 212 |

| Beets | 40 | 45 | 50 | 212 |

Note: These are general guidelines. Always refer to specific recipes for detailed instructions.

Determining Processing Time Based on Altitude

Altitude significantly impacts the boiling point of water, affecting the effectiveness of the canning process. A higher altitude necessitates a longer processing time to achieve the same sterilization effect.

To determine the correct processing time for your specific altitude, consult reliable canning resources or use a canning calculator that accounts for altitude. This is a crucial step to ensure proper preservation.

Importance of a Reliable Thermometer

Accurate temperature monitoring is essential for successful canning. A reliable thermometer ensures the water bath reaches and maintains the necessary temperature for a given altitude and food type. A fluctuating temperature can compromise the sterilization process, increasing the risk of foodborne illnesses. Using a thermometer that is accurate and well-maintained is vital.

A consistently monitored and accurate temperature ensures the safety and quality of the canned product.

Processing Time Comparison Chart for Different Food Types

This table provides a comparative overview of processing times for various food types. The table highlights the differences in processing times, aiding in proper planning for canning different food items.

| Food Type | General Processing Time (minutes) | Considerations |

|---|---|---|

| Low-acid vegetables (beans, corn, peppers) | 40-55 | Processing times increase with altitude. |

| High-acid fruits (tomatoes, jams) | 10-20 | Processing times are shorter due to the natural acidity. |

Cooling and Storage

Proper cooling and storage are crucial steps in the water bath canning process. These steps ensure the safety and quality of your canned goods, preventing spoilage and maintaining their flavor and texture. Following these guidelines will allow you to enjoy delicious homemade preserves for months to come.The cooling process allows the jars to seal properly, while proper storage protects the sealed jars from contamination and maintains the quality of the food.

Careful attention to detail during these final steps is essential to successful canning.

Cooling Methods

Proper cooling is essential to allow the jars to seal correctly. Incorrect cooling can prevent a vacuum seal, leaving the jars vulnerable to spoilage. Two primary methods exist for cooling your jars and canner.

- Air Cooling: Allowing the jars to cool completely in the canner without disturbing them is a common method. The steam escaping from the jars creates a vacuum seal. This is a straightforward method, requiring minimal effort and no additional equipment. Do not move the jars or open the canner lid until the jars have finished cooling.

- Water Cooling: Immersing the canner and jars in cold water is another viable option. This accelerates the cooling process, allowing the jars to cool more quickly. This is particularly helpful in warmer climates, as the water bath effectively dissipates the heat from the jars and canner. Place the canner in a sink or tub filled with cold water and let it cool to room temperature.

Importance of Complete Cooling

Allowing the jars to cool completely before checking the seals is vital. A crucial part of this process is ensuring the vacuum seal forms correctly. The glass jars shrink slightly as they cool, creating a vacuum seal. If the jars are checked too soon, the seal may not have formed properly. Checking for seals before the jars are completely cooled could lead to potentially spoiled food.

Checking for Seal Integrity

Properly checking the seal is a critical step in ensuring the safety and quality of your canned goods. A vacuum seal prevents bacteria from entering the jar and ensures the safety of the food.

- Visual Inspection: After the jars have cooled completely, carefully examine the lids. A properly sealed jar will have a concave or slightly indented lid. A bulging lid may indicate pressure buildup. If a lid is loose or bulging, it is not sealed and should be refrigerated. Do not consume canned goods with bulging or loose lids.

- Finger Pressure Test: Gently press down on the center of the lid. A properly sealed lid will not flex or move. If the lid flexes, it is not sealed and should be refrigerated.

Storage Practices

Proper storage of canned goods is critical to maintaining their quality and safety.

- Cool, Dark, Dry Location: Store canned goods in a cool, dark, and dry location. Avoid locations exposed to direct sunlight or excessive heat. A pantry or storage room provides a suitable environment.

- Proper Labeling: Label each jar with the contents, date, and processing date. This will help you keep track of your canned goods and ensure you use them before their best-by date. This is important for both food safety and tracking.

Troubleshooting Common Issues

Maintaining the safety and quality of your canned goods hinges on careful attention to detail during the entire process. Troubleshooting potential problems promptly can prevent spoilage and ensure the preservation of your homegrown bounty. Knowing how to address issues like leaks or unsealed jars is crucial for successful canning.Troubleshooting canning issues is an important aspect of the process.

Understanding the potential causes and appropriate solutions will allow you to confidently resolve problems and enjoy your home-canned food. This section Artikels common problems, their potential causes, and effective solutions.

Causes of Jar Not Sealing

Proper sealing is essential for preserving food in jars. Several factors can contribute to a jar not sealing. Understanding these factors is crucial to prevent food spoilage and ensure safety.

- Improper Jar Preparation: Dirt, grease, or other contaminants on the jar rim or lid can prevent a proper seal. Thoroughly cleaning jars and lids before use is vital. Ensure that the rims are clean and free from any debris or residue. This will ensure a proper seal is achieved.

- Incorrect Processing Time or Temperature: Insufficient processing time or temperature may not eliminate harmful bacteria, resulting in a lack of seal. Adhering to the specific processing times and temperatures for your chosen recipe is paramount for a successful seal. For example, high-acid foods like tomatoes may require a shorter processing time than low-acid foods like green beans.

- Improper Lid Placement: Misplacing the lid or placing it incorrectly on the jar can prevent the lid from sealing properly. Ensure the lid is placed directly on the jar rim and that it is not damaged or bent.

- Incorrect Vacuum in the Jar: A vacuum seal is necessary for proper preservation. If the vacuum is not properly created during processing, the jar will not seal. Proper vacuum is essential for safety and preservation. A lack of vacuum is often due to improper processing.

- Damaged Jars or Lids: Cracks, chips, or dents in the jars or lids can hinder proper sealing. Inspect jars and lids for damage before using them. Any damage should result in the jar being discarded.

Addressing Unsealed Jars

If a jar doesn’t seal, careful consideration is necessary. Unsealed jars present a food safety risk. Follow these steps if a jar doesn’t seal.

- Assess the Situation: Examine the jar to determine the cause. Was there any damage to the jar or lid? Were the processing times and temperatures followed correctly? Note the circumstances for future reference.

- Reprocess the Jar: For jars that don’t seal, carefully reprocess them in a water bath canner. Increase the processing time by 10 minutes to ensure proper sterilization and a good seal. The increased time is a preventative measure to eliminate bacteria and ensure proper preservation.

- Discard the Contents: If the jar remains unsealed after reprocessing, discard the contents immediately. Do not reuse the food in the jar. Food safety is paramount; do not take any risks with potentially spoiled food.

Troubleshooting Flowchart

This flowchart guides you through troubleshooting canning issues.

| Issue | Possible Cause | Solution |

|---|---|---|

| Jar doesn’t seal | Improper jar preparation, incorrect processing, damaged jar/lid | Check for damage, reprocess for 10 minutes longer, discard if unsealed after reprocessing. |

| Leak | Damaged jar or lid, improper sealing | Discard the jar and contents, check for damage, use a new jar and lid. |

| Jar swells | Improper sealing, microbial growth | Discard the jar and contents, investigate the cause, use new jars and lids for future batches. |

Safety Precautions and Considerations

Safe canning practices are paramount to prevent foodborne illnesses and ensure the quality and preservation of your homemade canned goods. Adherence to these guidelines ensures the safety and enjoyment of your canned products. Following proper procedures and paying close attention to details is crucial for a successful and safe canning experience.Proper handling of hot equipment and jars, safe food handling, and a meticulous checklist of considerations are essential aspects of the canning process.

This section details the critical safety precautions that must be followed to avoid potential risks.

Importance of Following Safety Guidelines

Safe canning procedures are essential to ensure the safety and quality of your homemade canned goods. These procedures are designed to destroy harmful bacteria and other microorganisms that can cause foodborne illnesses. Failure to follow these guidelines can result in spoiled food, health problems, and even serious illnesses. Adherence to established safety guidelines is critical for the successful and safe outcome of your canning efforts.

Safety Precautions for Handling Hot Equipment and Jars

Proper handling of hot equipment and jars is crucial for preventing burns and injuries. Use oven mitts or pot holders to handle hot jars and canners. Allow adequate time for equipment to cool before handling. Avoid touching hot surfaces directly. Be mindful of the potential for burns, especially when dealing with hot glass or metal.

Always use appropriate protective gear.

Safe Food Handling Practices During the Canning Process

Maintaining safe food handling practices throughout the entire canning process is vital for preventing contamination. Thoroughly wash all utensils, cutting boards, and countertops with hot, soapy water. Avoid cross-contamination by using separate cutting boards for raw and cooked foods. Keep work areas clean and sanitized. Use clean and sanitized equipment throughout the canning process.

Proper handwashing is also critical.

Checklist of Safety Considerations for the Entire Canning Process

A thorough checklist of safety considerations ensures a safe and successful canning experience. This checklist should be meticulously followed to minimize potential risks and maintain the integrity of your canned foods.

- Sanitation: Ensure all equipment, jars, and utensils are thoroughly cleaned and sanitized before use. This includes washing surfaces with hot, soapy water and a sanitizing solution. This step prevents contamination of food.

- Equipment Inspection: Inspect canner and jars for any damage or defects before use. Cracks or chips in jars or damage to the canner can lead to failure of the canning process and could result in spoiled food.

- Accurate Measurement: Precise measurements of ingredients and processing times are critical for the effectiveness of the canning process. This ensures proper preservation and safety. Incorrect measurements can result in inadequate processing times and potential spoilage.

- Proper Sealing: Ensure jars are sealed properly. Proper sealing prevents the growth of harmful bacteria and ensures the integrity of the canned food. This is a critical step to maintain the quality of your canned products.

- Processing Time and Temperature: Adhere strictly to recommended processing times and temperatures for each type of food. This is crucial for destroying harmful microorganisms and ensuring food safety. Using incorrect times or temperatures can lead to bacterial growth and potential illness.

- Cooling and Storage: Allow jars to cool completely before storing them in a cool, dark place. Improper cooling or storage can affect the safety and quality of your canned goods. Storing in a cool, dark environment prevents further bacterial growth.

- Troubleshooting: Be prepared to troubleshoot any issues that may arise during the canning process. Thorough understanding of potential problems will ensure that any issues can be resolved quickly.

Legal and Regulatory Considerations

Understanding the legal and regulatory framework surrounding food preservation, particularly canning, is crucial for ensuring the safety and quality of your home-canned goods. These guidelines are designed to protect consumers from potential health risks associated with improperly processed foods. Compliance with these regulations demonstrates a commitment to food safety and protects both you and your consumers (if applicable).Compliance with food safety regulations is essential for the well-being of consumers and the integrity of the canning process.

Regulations exist to safeguard public health by preventing the growth of harmful microorganisms and ensuring proper food preservation methods are followed. This ensures that canned goods are safe for consumption and maintain their quality.

National Food Safety Guidelines

National food safety guidelines often cover essential aspects of food processing and preservation, including canning. These guidelines provide a baseline for safe food handling practices, ensuring that canned goods are free from harmful bacteria and pathogens. These regulations generally Artikel proper processing temperatures and times for various food types to ensure the elimination of harmful microorganisms. Following these guidelines ensures that your canned goods are safe to eat.

Local Regulations

While national guidelines provide a framework, local jurisdictions may have specific regulations for food processing and canning. It is important to check with your local health department or equivalent authority for any specific requirements or guidelines. These regulations might address things like permits, inspections, and labeling standards. Local requirements can vary significantly, so it’s vital to know what standards apply in your area.

Importance of Understanding Regulations

Understanding food safety regulations is paramount to successful and safe canning. This knowledge ensures you use the appropriate methods and procedures, minimizing the risk of foodborne illnesses. Properly understanding and adhering to the guidelines for canning is essential for ensuring that your home-canned goods are safe to consume.

Summary of Canning Regulations

| Region | Key Regulations |

|---|---|

| United States | The U.S. Department of Agriculture (USDA) provides guidelines and recommendations for home canning. These recommendations often cover processing times and temperatures for various foods. |

| Canada | Health Canada offers similar guidelines for home canning, outlining safe practices and providing resources for safe food preservation. |

| European Union | The European Union has regulations that may impact food preservation, including home canning. Consult relevant EU guidelines for specific requirements and details. |

Note: This table provides a general overview and is not exhaustive. Always consult the specific guidelines from the relevant authority for your region.

Advanced Canning Techniques

Expanding upon the fundamental water bath canning process, this section explores advanced techniques for enhancing your canning endeavors. These methods allow for greater control over flavor profiles, preservation, and overall quality of your home-canned goods. From adding aromatic spices to utilizing specialized jar types, these advanced techniques elevate the experience of water bath canning beyond the basics.This exploration delves into optional techniques and variations within water bath canning, demonstrating how experienced canners can adapt their methods for specific food types.

It also highlights the importance of understanding the proper jar and lid selection for achieving optimal preservation and safety. Mastering these advanced techniques can lead to more flavorful and visually appealing canned goods, ultimately extending the enjoyment of your homegrown harvests.

Spice and Herb Additions

Adding spices and herbs before canning can significantly enhance the flavor of your preserved foods. Properly chosen aromatics can complement the natural flavors of your vegetables or fruits, adding depth and complexity to the final product. Consider the type of food you’re canning and select spices that will enhance, rather than overpower, the inherent taste. For instance, cinnamon and cloves pair well with apples, while thyme and rosemary enhance the flavor of tomatoes.

Variations for Specific Food Types

Different food types respond uniquely to various canning techniques. Understanding these variations is crucial for achieving optimal results.

- Fruits: Some fruits benefit from a sugar syrup, which helps to maintain their texture and sweetness during preservation. Others, like peaches and pears, might require a short blanching process before canning to help maintain their shape and firmness. A brief blanching time can significantly enhance the final appearance of canned fruits.

- Vegetables: Certain vegetables, such as green beans or corn, can be prepped in different ways before canning. Some benefit from a brief blanch, while others may not require it. Careful attention to specific vegetable varieties will yield better results.

Jar and Lid Selection

The choice of jars and lids is critical for successful canning. Not all jars and lids are created equal. Using the correct jar and lid for the specific food item is crucial for preventing leaks and maintaining the safety of your preserved goods.

- Mason Jars: Standard mason jars are the most common choice for water bath canning. They’re durable, easy to clean, and widely available. However, ensure that the jars are properly sized for the food item being canned.

- Lids and Rings: Use only new, properly fitted lids and rings for each canning batch. Ensure that the lids are properly sealed to prevent spoilage. Regular inspection of lids and rings for any damage or wear is crucial.

Advanced Methods for Specific Foods

Certain foods, like jams and jellies, require unique techniques. Understanding these techniques will help preserve their texture, flavor, and overall quality.

- Jams and Jellies: Jams and jellies require careful attention to the sugar and pectin content to ensure proper setting and preservation. Adjusting these ingredients based on the type of fruit used can lead to optimal results. Precise measurements of sugar and pectin are important for a successful outcome.

- Pickles: Pickling involves adding salt, vinegar, or other ingredients to the vegetables to create a tangy flavor. Using the right combination of spices and herbs can significantly enhance the taste and appeal of your pickles. The specific types of spices and herbs used in pickling should be carefully selected to achieve the desired flavor.

Resources and Further Learning

Mastering water bath canning involves not only understanding the process but also continuous learning and adaptation. This ongoing education ensures your efforts result in safe and delicious home-preserved food. This section provides valuable resources to expand your knowledge and refine your canning skills.

Reliable Resources for Further Learning

Expanding your knowledge base beyond this guide is crucial for mastering water bath canning. Numerous reliable resources are available to provide additional support and guidance. These resources offer in-depth explanations, detailed instructions, and practical tips that enhance your understanding of canning.

- National Center for Home Food Preservation (NCHFP): The NCHFP, a resource from the USDA, is an invaluable source of information on safe food preservation techniques, including water bath canning. Their website provides comprehensive guides, fact sheets, and videos to ensure you have a clear understanding of the canning process and potential issues. This resource is a cornerstone of reliable information on food preservation.

- University Extension Offices: Local university extension offices offer workshops, classes, and resources on home food preservation. They often provide practical demonstrations and answer specific questions related to your area’s climate and growing conditions, customizing canning knowledge for particular regions. These experts can address your specific needs.

- Reputable Food Preservation Blogs and Websites: Numerous websites and blogs focus on home food preservation. Look for those with clear, concise information from experienced canners, backed by scientific principles and established guidelines. These sources offer various perspectives and detailed explanations of specific food items, along with potential challenges and solutions.

Importance of Continuous Learning

Food preservation techniques are dynamic, and best practices evolve based on research and experience. Continuous learning about food preservation techniques is essential for ensuring safety and achieving optimal results. Modern research frequently introduces new insights and refinements.

- Adapting to New Information: Scientific understanding and best practices evolve over time. Staying updated allows you to adapt to new information and refine your approach for the safest and most effective results. Staying informed ensures you utilize the latest recommendations for food preservation.

- Addressing Changing Circumstances: Factors such as your location, climate, and the types of food you’re preserving can influence your canning process. Continuously learning allows you to adjust your methods to meet these unique needs and achieve the best results. Adjusting canning methods based on environmental factors enhances safety and preservation effectiveness.

- Preventing Mistakes: Learning from others’ experiences and understanding the potential challenges helps avoid common mistakes. Learning the potential issues and their solutions allows you to tackle unexpected circumstances with confidence and prevent any negative outcomes. This ensures a successful outcome in your canning endeavors.

Bibliography

- The Ball Blue Book Guide to Preserving by Ball Corporation: This book provides comprehensive instructions and detailed information on various canning methods, including water bath canning. This guide offers a wide range of recipes and information on preparing and preserving different food items.

- The Complete Guide to Home Canning by the USDA: This guide offers comprehensive instructions and detailed information on safe food preservation techniques. It covers various canning methods and food types. This comprehensive guide ensures thorough understanding of the process.

- [Link to reputable website]: Insert links to specific websites with valuable information and resources for water bath canning, providing a rich source of knowledge.

Last Word

In conclusion, this comprehensive guide has provided a step-by-step approach to safely using a water bath canner. By understanding the importance of proper food preparation, equipment selection, and processing techniques, you can confidently preserve your favorite low-acid foods. Remember to prioritize safety throughout the entire process, and always consult reliable resources for further information. With careful attention to detail and a thorough understanding of the procedures, you can enjoy the fruits (and vegetables!) of your labor for months to come.