Harnessing the power of the sun for food preservation has never been easier. This comprehensive guide provides a step-by-step approach to building a simple solar dehydrator. From understanding the fundamental principles of solar dehydration to practical construction techniques, this resource is designed to empower beginners and experienced crafters alike.

Discover the advantages of this eco-friendly method, learning how to prepare food for optimal drying and how to effectively monitor the process. Detailed instructions and helpful diagrams make the entire project accessible and engaging.

Introduction to Solar Dehydrators

Solar dehydration is a method of preserving food using the sun’s energy. It’s a simple, cost-effective, and environmentally friendly technique that has been used for centuries. This method effectively removes moisture from food, slowing down the growth of microorganisms and extending its shelf life. By understanding the principles behind this process, you can build your own solar dehydrator and enjoy the benefits of preserving fresh produce.The fundamental principle behind solar dehydration is the evaporation of water from food items.

Sunlight provides the heat necessary to drive this process, concentrating the nutrients and flavors while preventing spoilage. This process reduces the water content, thus inhibiting the growth of bacteria and fungi. Consequently, the food becomes more stable and can be stored for longer periods.

Basic Principles of Solar Dehydration

Solar dehydration leverages the sun’s energy to create a controlled drying environment. The process relies on the heat from sunlight to evaporate moisture from food, reducing its water content. This reduction inhibits microbial growth and increases the shelf life of the food. Key factors include the intensity and duration of sunlight, air circulation, and the materials used for the dehydrator’s construction.

Advantages of Using a Solar Dehydrator

- Environmental Friendliness: Solar dehydration requires no fossil fuels, making it a sustainable method of food preservation. This reduces your carbon footprint and promotes environmentally conscious practices.

- Cost-Effectiveness: Building a solar dehydrator is generally inexpensive compared to other food preservation methods, especially when considering the long-term cost savings from avoiding food waste and using less energy.

- Accessibility: Solar dehydration can be practiced in various regions, including those with limited access to electricity or refrigeration. The readily available solar energy makes it a versatile option for preservation in diverse locations.

- Nutritional Retention: Properly constructed solar dehydrators can maintain a significant portion of the food’s nutritional value, unlike some other preservation methods.

Disadvantages of Using a Solar Dehydrator

- Weather Dependence: Solar dehydration is dependent on sunlight, meaning it may not be reliable in areas with cloudy or rainy weather. Consequently, inconsistent weather conditions can impede the process, resulting in slower drying times or even halting the process altogether.

- Drying Time: The drying time for food items using a solar dehydrator can be significantly longer compared to using electric dehydrators, which have consistent heat sources. The drying time is influenced by the intensity of sunlight, the humidity, and the type of food being dried.

- Food Safety Concerns: If not properly maintained, solar dehydrators can become breeding grounds for microorganisms. This highlights the need for diligent cleaning and sanitization procedures to ensure food safety.

- Limited Capacity: Home-built solar dehydrators typically have a smaller capacity compared to commercial dehydrators, which might be a limitation for large-scale food preservation efforts.

Brief History of Solar Dehydration

Solar dehydration has been practiced for millennia. Ancient civilizations, aware of the preservation properties of the sun, employed various techniques, such as spreading food on rooftops or utilizing simple, open-air structures to dry fruits, vegetables, and meats. Early methods included laying food out on flat surfaces exposed to direct sunlight. These early methods laid the groundwork for the more sophisticated and organized systems used today.

The historical practice demonstrates the enduring effectiveness and practicality of this ancient technique.

Materials Needed

Building a simple solar dehydrator requires a thoughtfully chosen collection of materials. Careful consideration of each component’s function and the desired durability is key to ensuring the dehydrator’s effectiveness and longevity. The specific materials selected will influence the overall cost and the dehydrator’s performance in different climates.

Essential Components

The core components of a basic solar dehydrator are a box-like structure to hold the food, a method for directing sunlight, and a means to maintain airflow. The precise specifications of these components can be adapted to specific needs and available resources.

- Box Structure: A sturdy, lightweight box is crucial for holding the food. This could be constructed from wood, plywood, or even repurposed materials. Dimensions will depend on the intended capacity and desired drying area. A typical size for a simple dehydrator might range from 2 feet by 2 feet by 3 feet, but smaller or larger sizes can be created depending on the user’s needs.

Consider the weight of the food items to be dried and the stability requirements for the structure.

- Insulation (Optional): Insulation material, such as corrugated cardboard, can be placed between the interior and exterior walls of the box. This layer can significantly reduce heat loss, especially in cooler climates. This helps maintain the temperature inside and optimize drying efficiency. Consider the climate and expected temperatures to determine the necessity of insulation.

- Glass or Transparent Plastic Sheets: A clear material, like glass or clear plastic sheeting, is essential for capturing and focusing sunlight. This will be used as a cover for the box, creating a greenhouse effect to increase the temperature inside. The size should match the dimensions of the box structure. For instance, a 2-foot by 2-foot box would need a similar-sized sheet of glass or plastic.

- Support Structure: Lightweight supports are necessary to elevate the glass or plastic cover above the box, creating an air gap. This gap will aid in air circulation, preventing the food from getting too hot. The supports can be constructed from wood, metal, or even PVC pipes, depending on the available resources and desired durability. They must be strong enough to hold the weight of the cover and support its position.

- Air Circulation Materials (Optional): Adding material for improved airflow inside the dehydrator, such as mesh or screen, can significantly increase the efficiency of the drying process. This is often used to create a gap between the cover and the box, facilitating airflow. The materials used for this will depend on availability and the desired level of airflow.

Material Options and Cost Estimates

The cost of materials will vary based on the specific type and quantity. For example, a larger dehydrator will naturally involve a higher material cost. Estimates are approximate and can vary depending on location and retailer.

| Material | Description | Approximate Cost (USD) | Advantages | Disadvantages |

|---|---|---|---|---|

| Wood (Pine) | Common, readily available, relatively affordable. | $20 – $40 | Easy to work with, good structural strength for simple designs. | Can be susceptible to moisture damage if not treated properly. |

| Plywood | Stronger and more consistent than wood. | $25 – $50 | Excellent structural support, more durable than most wood. | Can be more expensive than wood. |

| Recycled Plastic | Repurposed containers or sheeting. | $5 – $20 (depending on source) | Cost-effective, environmentally friendly. | May not be as strong as wood or plywood. |

| Glass | Clear, durable material for covering. | $15 – $30 (depending on size) | Excellent light transmission. | More fragile than plastic. |

| Plastic Sheeting (Clear) | Lightweight, readily available. | $10 – $25 (depending on size) | Relatively inexpensive, easy to work with. | May not be as durable as glass. |

Alternative Materials

If specific materials are unavailable or excessively expensive, alternative materials can be used. For instance, repurposed materials like cardboard boxes or plastic containers can be used for the box structure. The selection of materials should consider factors such as strength, durability, and availability in the local area.

Design and Construction

Constructing a simple solar dehydrator involves carefully selecting and assembling components to maximize sunlight capture and airflow for efficient food preservation. This section details the step-by-step procedure, emphasizing the importance of proper ventilation and diverse design options. A well-designed solar dehydrator will effectively reduce moisture content, preserving food quality and extending its shelf life.The design of a solar dehydrator hinges on optimizing the interaction between sunlight, airflow, and the food being dehydrated.

Proper ventilation is critical to prevent the growth of mold and bacteria, and to ensure uniform drying. A well-ventilated design will also reduce the time needed to dehydrate the food. By understanding the principles of heat transfer and airflow, you can create a robust and efficient drying system.

Step-by-Step Construction Procedure

This section details the key steps for assembling a basic solar dehydrator. Precise execution of each step is crucial for a functional and effective device.

- Frame Construction: A sturdy frame, typically made of wood or metal, forms the base of the dehydrator. This frame will support the entire structure and provide stability. Ensure the frame is strong enough to withstand the weight of the drying trays and the heat from the sun.

- Tray Placement: The frame will hold multiple trays for the food to be dehydrated. These trays are commonly made of wire mesh or perforated metal sheets, allowing for excellent airflow around the food. Ensure the trays are evenly spaced within the frame.

- Covering and Ventilation: A transparent cover, such as glass or plastic sheeting, is essential for trapping solar energy. Ventilation is crucial to prevent moisture buildup. Small openings or vents in the cover will facilitate air circulation, promoting even drying and preventing condensation. Proper ventilation will also aid in maintaining a consistent temperature inside the dehydrator.

- Assembly and Testing: Carefully assemble the various components. Place the trays within the frame, ensuring proper spacing. Position the cover, ensuring proper ventilation. Test the dehydrator by placing a small amount of food on the trays and observing the drying process. Adjustments to ventilation or cover placement may be necessary.

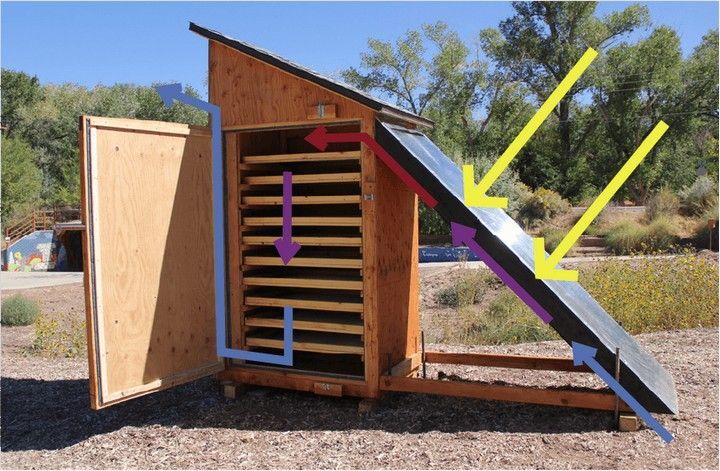

Diagram of Solar Dehydrator Design

The following diagram provides a visual representation of a simple solar dehydrator. Note the importance of the ventilation holes in the cover and the spacing between the trays.

(A detailed diagram illustrating the structure should be included here. The diagram should clearly show the frame, trays, cover, and ventilation openings. The diagram should be labelled to show the different components. An example could be a simple drawing, using various shapes and lines to represent the structure and components of the solar dehydrator.)

Importance of Proper Ventilation

Adequate ventilation is essential for the successful operation of a solar dehydrator. Proper airflow prevents the buildup of moisture, which can lead to spoilage. This consistent airflow helps maintain a suitable temperature inside the dehydrator for efficient dehydration and prevents mold or bacterial growth.

Types of Solar Dehydrator Designs

Different designs cater to varying needs and space constraints.

- Simple Box Design: This design is the most basic, using a box-like structure with a transparent cover and ventilation openings. It’s suitable for smaller-scale drying operations.

- Elevated Platform Design: This design elevates the dehydrator off the ground, providing better airflow and preventing moisture buildup from the ground. This can help to improve drying efficiency.

- Multi-Tiered Design: This design features multiple tiers, allowing for the dehydration of more food at once. It’s ideal for larger-scale drying operations and is more space-efficient than the basic design.

Assembling Components

The specific assembly procedure will vary based on the chosen design. However, a general approach involves carefully connecting the frame, trays, and cover. The following points summarize the key considerations.

- Frame Construction: Ensure the frame is sturdy and properly supports the trays and cover.

- Tray Placement: Position the trays evenly spaced within the frame to allow for adequate airflow.

- Cover Attachment: Secure the cover to the frame, ensuring proper sealing to minimize heat loss and prevent moisture from entering.

- Ventilation Holes: Position the ventilation holes strategically to maximize airflow.

Solar Energy Collection

Maximizing solar energy collection is crucial for the efficiency of a solar dehydrator. Proper orientation, location, and consideration of weather conditions are vital for achieving optimal drying results. By understanding these factors, you can significantly increase the effectiveness of your dehydrator and ensure that your harvested produce dries quickly and evenly.Effective solar energy collection hinges on capturing the maximum amount of sunlight possible.

This is achieved through careful planning and strategic placement, allowing the dehydrator to absorb the highest intensity of solar radiation throughout the day.

Optimal Orientation and Angle

Proper orientation and angling of the dehydrator are essential for maximizing sunlight exposure. The optimal angle for maximum solar energy absorption depends on the latitude and time of year. During the summer months, a more shallow angle might be ideal, whereas a steeper angle might be necessary during the winter. For example, in the northern hemisphere, during summer, the dehydrator should be oriented facing south to capture the direct sunlight.

- South-Facing Orientation: In the Northern Hemisphere, a south-facing orientation generally allows for maximum exposure to the midday sun, leading to the most efficient drying. Adjustments for seasonal variations in sunlight angles are critical.

- Adjustable Angle: A dehydrator with an adjustable angle allows for optimization throughout the year. The angle should be adjusted based on the position of the sun, maximizing the surface area exposed to direct sunlight.

- Tracking Systems: Sophisticated dehydrators may include motorized tracking systems that automatically adjust the angle of the dehydrator throughout the day, ensuring optimal sunlight exposure. This is particularly beneficial in areas with significant seasonal variations in solar angle.

Choosing the Best Location

The chosen location for the dehydrator significantly impacts its performance. A location with ample sunlight exposure, minimal shade, and good ventilation is ideal. Consider the surrounding environment and potential obstacles to sunlight.

- Sunlight Exposure: Select a location that receives direct sunlight for the majority of the day. Avoid areas with significant shade from trees or buildings.

- Ventilation: Adequate ventilation is crucial for preventing moisture buildup and ensuring even drying. A location with good airflow will contribute to more efficient drying.

- Accessibility: Select a location that is easily accessible for loading and unloading the dehydrator. A convenient location will minimize time and effort required for maintenance and operation.

Factors Affecting Solar Energy Collection

Several factors influence the effectiveness of solar energy collection for a dehydrator. These factors need to be considered to ensure optimal drying results.

- Cloud Cover: Cloudy weather significantly reduces the amount of solar radiation reaching the dehydrator. This will impact drying times and potentially necessitate alternative drying methods.

- Atmospheric Conditions: Dust, pollutants, and other atmospheric particles can reduce the amount of sunlight reaching the dehydrator. Regular cleaning of the dehydrator can mitigate these effects.

- Material Reflectivity: The reflectivity of the dehydrator’s materials impacts how much sunlight is absorbed. Darker surfaces generally absorb more solar energy than lighter surfaces.

Weather Conditions and Performance

Weather conditions significantly impact the performance of a solar dehydrator. Understanding these effects will help in managing expectations and adapting drying procedures as needed.

- High Humidity: High humidity can prolong drying times, as moisture in the air can hinder the evaporation process. This is important to note as higher humidity will increase the time it takes to dry the produce.

- Rain: Rainfall will interrupt the drying process, requiring adjustments to drying times and methods.

- Wind: Moderate wind can be beneficial for ventilation and drying. However, excessive wind can cause moisture to evaporate too quickly, potentially leading to uneven drying.

Food Preparation and Loading

Proper food preparation and loading are crucial steps in the solar dehydration process. Careful attention to these steps ensures that the food dehydrates efficiently and maintains its nutritional value and desirable texture. This section details the essential steps in preparing food for solar dehydration, emphasizing the importance of proper food preparation and appropriate food thickness for optimal results.

Food Preparation Steps

Preparing food for solar dehydration involves several key steps to maximize efficiency and quality. Firstly, select the desired food items and ensure they are fresh and of good quality. Thorough washing and cleaning are essential to remove any dirt or contaminants. Subsequently, the food must be cut or sliced into uniform pieces. This uniform size ensures even drying and prevents some pieces from drying out before others.

The consistency of the final product depends on the initial preparation steps.

Importance of Proper Food Preparation

Proper food preparation is critical for successful solar dehydration. Uneven sizes and shapes of food pieces can lead to inconsistent drying times. Some pieces might become overly dry and brittle while others remain moist. This uneven drying can compromise the food’s texture and nutritional value. Furthermore, improper cleaning can introduce harmful bacteria or contaminants into the food, affecting its safety and quality.

Appropriate Food Thickness for Efficient Dehydration

The thickness of the food pieces directly affects the dehydration process. Food that is too thick will take longer to dry completely, potentially leading to the development of undesirable flavors or textures. Conversely, food that is too thin might dry out too quickly, resulting in a loss of moisture and nutrients. Optimal thickness is crucial for efficient dehydration, ensuring uniform moisture removal and the preservation of desirable food characteristics.

For example, slicing fruits and vegetables into 1/4-inch thick pieces is a good starting point for experimentation.

Suitable Foods for Solar Dehydration

The following table provides a general guideline of suitable foods for solar dehydration, categorized by type. Keep in mind that specific results may vary depending on the climate, solar intensity, and the design of the solar dehydrator.

| Food Type | Examples |

|---|---|

| Fruits | Apples, Bananas, Berries, Mangoes, Pears |

| Vegetables | Beans, Carrots, Peppers, Squash, Tomatoes |

| Herbs | Basil, Chives, Mint, Oregano |

| Meats | Beef jerky, poultry jerky |

| Mushrooms | Button mushrooms, Oyster mushrooms |

Methods for Arranging Food on Trays

Proper arrangement of food on the trays is vital for even dehydration. Uniform spacing prevents food pieces from sticking together, ensuring that each piece receives adequate exposure to air circulation and sunlight. Moreover, overlapping pieces can hinder the drying process, leading to potential issues with quality. Use of food separators (like parchment paper) will aid in keeping the pieces separated.

- Spacing: Ensure adequate space between each piece of food. A general guideline is to maintain a 1/2-inch gap between pieces.

- Layering: Avoid piling food pieces on top of each other to ensure even air circulation. Layering should be done in a single layer, if possible.

- Orientation: Position the food pieces in a way that maximizes surface area exposure to sunlight and air circulation. This can involve cutting the food into smaller pieces, or using a specific orientation.

Monitoring and Maintenance

Proper monitoring and maintenance are crucial for ensuring the longevity and optimal performance of your solar dehydrator. Consistent observation of the dehydration process, coupled with appropriate adjustments and preventive maintenance, will guarantee successful results and a long-lasting tool.Effective monitoring allows for prompt identification of any issues and enables timely adjustments, ultimately optimizing the drying process. Regular maintenance, on the other hand, safeguards the dehydrator’s structural integrity and operational efficiency, leading to a longer lifespan and more consistent outcomes.

Monitoring the Dehydration Process

Careful monitoring of the dehydration process is essential for achieving optimal results. This involves regularly checking the moisture content of the food being dehydrated. Changes in the food’s texture, color, and consistency provide valuable indicators of the drying progress. Use a moisture meter for precise measurements. If using a moisture meter, ensure proper calibration and usage instructions are followed.

Adjusting the Dehydrator’s Position and Components

Optimizing the dehydrator’s performance involves careful adjustment of its position and components. Adjusting the angle of the dehydrator to maximize solar exposure is paramount. A south-facing position is ideal in most cases, but local conditions may warrant adjustments. Monitoring the temperature inside the dehydrator is crucial. Temperature variations may necessitate adjustments to the dehydrator’s position or the addition of reflective materials to improve solar energy capture.

Common Issues During Dehydration

Several issues can arise during the dehydration process. One potential problem is uneven drying. This can occur if the food items are not evenly spaced or if the dehydrator is not positioned optimally. Another potential problem is mold growth, which can occur if the food is not adequately prepared or the dehydrator is not properly cleaned. Consistent monitoring and prompt addressing of issues will minimize problems and ensure quality outcomes.

Maintaining the Dehydrator

Regular maintenance extends the lifespan of your solar dehydrator. Regular cleaning of the trays and interior components is crucial. Avoid using harsh chemicals or abrasive cleaners that might damage the materials. Thoroughly dry all components before storing to prevent mold or mildew buildup. Periodic inspection of the solar panel and the dehydrator’s structure for any damage or wear is important.

Troubleshooting Guide

This table provides a guide to common issues and their potential solutions:

| Issue | Potential Solution |

|---|---|

| Uneven drying | Ensure even spacing of food items, adjust dehydrator position for optimal solar exposure, and monitor temperature inside the dehydrator. |

| Mold growth | Thoroughly clean the trays and interior components after each use. Proper food preparation and drying are crucial. |

| Low drying rate | Adjust the dehydrator’s angle to maximize solar exposure. Check for obstructions preventing sunlight from reaching the dehydrator. |

| Damaged components | Repair or replace damaged parts promptly. Consult the manufacturer’s instructions or a qualified technician for repairs. |

Dehydration Time and Temperature

Achieving optimal dehydration requires careful consideration of time and temperature. Understanding the factors influencing these parameters ensures efficient and high-quality results. Precise control over the process maximizes nutrient retention and prevents undesirable changes in the food’s texture and taste.

Factors Affecting Dehydration Time

Several factors influence the time needed to dehydrate food. These include the initial moisture content of the food, the ambient temperature of the solar dehydrator, and the type of food being processed. The thickness of the food pieces also plays a significant role. Thicker pieces will require longer drying times to ensure complete moisture removal.

Approximate Dehydration Times for Different Foods

The table below provides approximate dehydration times for various food types in a typical solar dehydrator. These times are estimations and may vary based on the specific conditions.

| Food Type | Approximate Dehydration Time (hours) |

|---|---|

| Sliced Apples | 4-6 |

| Sliced Peaches | 5-8 |

| Cherry Tomatoes | 3-5 |

| Sliced Carrots | 6-8 |

| Mushrooms | 2-4 |

| Herbs | 1-3 |

Estimating Drying Time Based on Specific Food

Accurate estimation of drying time involves considering several aspects. Assess the thickness of the food slices. Thinner slices will dehydrate faster than thicker ones. The initial moisture content of the food also significantly affects drying time. High-moisture foods will require more time.

Additionally, the ambient temperature of the solar dehydrator plays a crucial role. Higher temperatures will expedite the dehydration process. Observe the food regularly, noting any changes in texture and appearance.

Temperature Range for Effective Dehydration

The ideal temperature range for effective dehydration in a solar dehydrator is typically between 40°C and 60°C (104°F and 140°F). Within this range, the food dehydrates efficiently without significant damage to its nutritional value. Maintaining a consistent temperature is essential for uniform drying.

Assessing Adequate Dehydration

Determining when food is adequately dehydrated involves a multi-faceted approach. The food should exhibit a flexible but firm texture, resembling a slightly chewy state. A crucial indicator is the food’s weight reduction. The food should lose a substantial amount of moisture, signifying effective dehydration. Another indicator is the food’s ability to crumble when pressed gently.

The food’s color should also be a consideration; a darker color indicates a reduced moisture content.

Safety Precautions

Ensuring safe operation of a solar dehydrator is crucial for both the user and the quality of the dehydrated food. Proper handling of materials, equipment, and the final product is essential to prevent accidents and maintain food safety. This section Artikels the critical safety measures to follow throughout the entire process.Careful attention to safety protocols is paramount when constructing and using a solar dehydrator.

Potential hazards can be mitigated through proactive measures. This section will address these measures, emphasizing the safe handling of materials, equipment, and the final dehydrated food products.

Handling Sharp Objects or Equipment

Sharp objects like knives, scissors, or even the metal components of the dehydrator frame should be handled with extreme care. Using protective gloves and ensuring a stable workspace are crucial to prevent cuts and injuries. Sharp objects should be stored securely in designated areas when not in use. Always double-check that the cutting area is clean and free of debris.

Proper Storage of Dehydrated Food

Dehydrated food, once properly processed, requires careful storage to maintain its quality and safety. Storage containers should be airtight and ideally made of food-grade materials. Storing the food in a cool, dry, and dark place will help to maintain its quality and prevent spoilage. Proper sealing and labeling of containers is important to track the type and date of the food.

For example, clearly labeled containers prevent cross-contamination and maintain the integrity of the food.

Emergency Procedures

Having a plan in place for potential emergencies is crucial. In case of a fire, a well-defined evacuation plan and knowledge of local fire safety procedures are essential. Knowing how to use fire extinguishers or other fire safety equipment is a significant part of preparedness. Similarly, in the event of cuts or other minor injuries, knowing how to apply first aid is vital.

It is recommended to keep a first-aid kit readily available, and to know the local emergency services numbers. Knowing where the nearest medical facility is located is also crucial in an emergency. Having a basic first-aid kit with bandages, antiseptic wipes, and pain relievers can make a significant difference.

Environmental Impact

A solar dehydrator offers a compelling alternative to traditional dehydration methods, presenting numerous environmental advantages. Harnessing the power of the sun reduces reliance on energy-intensive processes, contributing to a more sustainable approach to food preservation. By understanding the environmental benefits and the responsible use of this technology, we can appreciate its role in a more eco-conscious future.

Environmental Benefits of Solar Dehydration

Solar dehydration leverages a readily available and renewable energy source – sunlight. This drastically reduces the environmental footprint compared to methods that rely on fossil fuels for power. By reducing reliance on electricity, we lessen the demand for power generation, which often involves the emission of greenhouse gases and other pollutants.

Sustainability of Solar Dehydration Methods

Solar dehydration is inherently a sustainable practice. The process itself requires minimal intervention, relying primarily on the sun’s energy. The reduced need for fossil fuels directly contributes to a lower carbon footprint and lessens our dependence on finite resources. This sustainable method aligns with the principles of environmental stewardship.

Comparison with Other Dehydration Methods

Compared to electric dehydrators, solar dehydration offers a significant environmental advantage. Electric dehydrators consume electricity, which often comes from fossil fuel power plants, generating greenhouse gas emissions. Solar dehydration avoids these emissions and significantly reduces energy consumption, thereby lowering the overall environmental impact. The operational cost of a solar dehydrator is generally lower, as it uses a free and renewable resource.

Reduction in Fossil Fuel Reliance

Solar dehydration directly reduces reliance on fossil fuels by eliminating the need for electricity generation from non-renewable sources. This shift towards renewable energy sources helps mitigate climate change and promotes a more sustainable food system. Furthermore, the reduction in transportation of fossil fuel-based goods from industrial sources to consumers also contributes to a lower carbon footprint.

Minimizing Waste During Construction and Use

Careful material selection and construction techniques can minimize waste during the creation of a solar dehydrator. Choosing sustainable and readily available materials, such as locally sourced wood or recycled metal, helps reduce the environmental impact of the construction process. Proper maintenance and responsible food handling practices throughout the dehydration process will further minimize waste. Recycling any leftover materials, such as cardboard boxes or plastic wrap, will contribute to a more circular approach to the overall process.

Additional Tips and Variations

Building a simple solar dehydrator can be a rewarding experience, but further enhancements can significantly improve its efficiency and aesthetic appeal. These variations offer ways to optimize the dehydrator for specific needs and preferences. Understanding these techniques allows for a more personalized and effective approach to food preservation.Exploring advanced designs and modifications, alongside practical tips, allows for a more tailored dehydrating experience.

This section will delve into these improvements, ranging from enhancing energy collection to improving aesthetics, ensuring a satisfying and successful dehydrating process.

Improving Efficiency

Several strategies can enhance the dehydrator’s efficiency. Maximizing solar energy capture is crucial. A reflective surface, such as aluminum foil, placed beneath the trays can effectively increase the temperature inside the dehydrator. Experimentation with different materials can provide insight into the optimal configuration for specific climate conditions. Moreover, optimizing the airflow within the dehydrator can significantly affect the drying time.

Utilizing a mesh or grid system for the trays, enabling proper air circulation, is a key consideration.

Advanced Designs

Modifying the basic design can yield improved performance. Consider incorporating a glazing system for added insulation. Double-layered glass or plastic sheeting can significantly reduce heat loss, especially in cooler climates. A simple, yet effective, addition could be a small fan to actively circulate the air within the dehydrator, accelerating the drying process.

Aesthetics and Personalization

Personalizing the solar dehydrator can transform it from a functional tool into a visually appealing piece. Using attractive wood or bamboo for the frame can add a touch of natural beauty. Paints or finishes can be applied to the frame, creating a more personalized aesthetic. Consider the materials and colors to match your home’s decor or personal style.

Material Alternatives

Exploring alternative materials can lead to a more durable and effective dehydrator. Instead of using wood, consider using a sturdy metal frame, which can be more resistant to weather and warping. For the trays, use materials that are both non-reactive and easily cleaned, like stainless steel or food-grade plastic. The selection of materials is critical for both the long-term functionality and safety of the dehydrator.

Further Learning Resources

Numerous resources offer in-depth knowledge about solar dehydrators. Online forums and communities dedicated to sustainable living often provide valuable insights and advice from experienced users. Gardening and food preservation websites often feature detailed guides and tutorials, including troubleshooting and maintenance advice. Local agricultural extension offices or community colleges may offer workshops or courses on the topic, providing hands-on learning experiences.

- Online forums dedicated to sustainable living

- Gardening and food preservation websites

- Local agricultural extension offices

- Community colleges offering workshops

Concluding Remarks

In conclusion, constructing a solar dehydrator is a rewarding project that combines practicality with environmental consciousness. This guide provides a clear path for creating a sustainable solution for food preservation. By following the detailed steps, you can enjoy the fruits of your labor in the form of delicious, preserved food, while contributing to a more sustainable lifestyle. Embrace the power of the sun and the simplicity of solar dehydration!