Building a sturdy and comfortable milking stand for your goats is crucial for efficient and safe milking sessions. This guide provides a comprehensive approach, covering everything from initial design considerations to essential safety procedures and maintenance. We’ll explore various designs, materials, and measurements to ensure a practical and lasting solution for your needs. Understanding proper goat handling is paramount, and this guide prioritizes your goats’ well-being alongside the efficiency of the milking process.

This comprehensive guide walks you through the process of creating a simple yet effective milking stand for your goats. From selecting the right materials to ensuring optimal safety, this resource will equip you with the knowledge to build a stand tailored to your goats’ needs and your budget.

Introduction to Goat Milking Stands

A simple milking stand for goats is a crucial tool for efficient and safe milking practices. It elevates the goat, positioning the udder at a comfortable height for the milker, thus minimizing strain on both the animal and the person performing the task. Properly designed stands also facilitate hygiene and reduce the risk of injury to both the goat and the milker.

This allows for a more comfortable and productive milking session, contributing to the overall well-being of the animal and the quality of the milk produced.The importance of proper goat handling during milking cannot be overstated. A secure and stable milking stand is essential for ensuring the goat’s comfort and safety, minimizing stress and potential injuries. This is vital for maintaining a healthy and productive herd.

Safety precautions, such as ensuring the stand’s stability and providing adequate support for the goat, are paramount to prevent accidents and ensure a positive experience for both the goat and the milker.

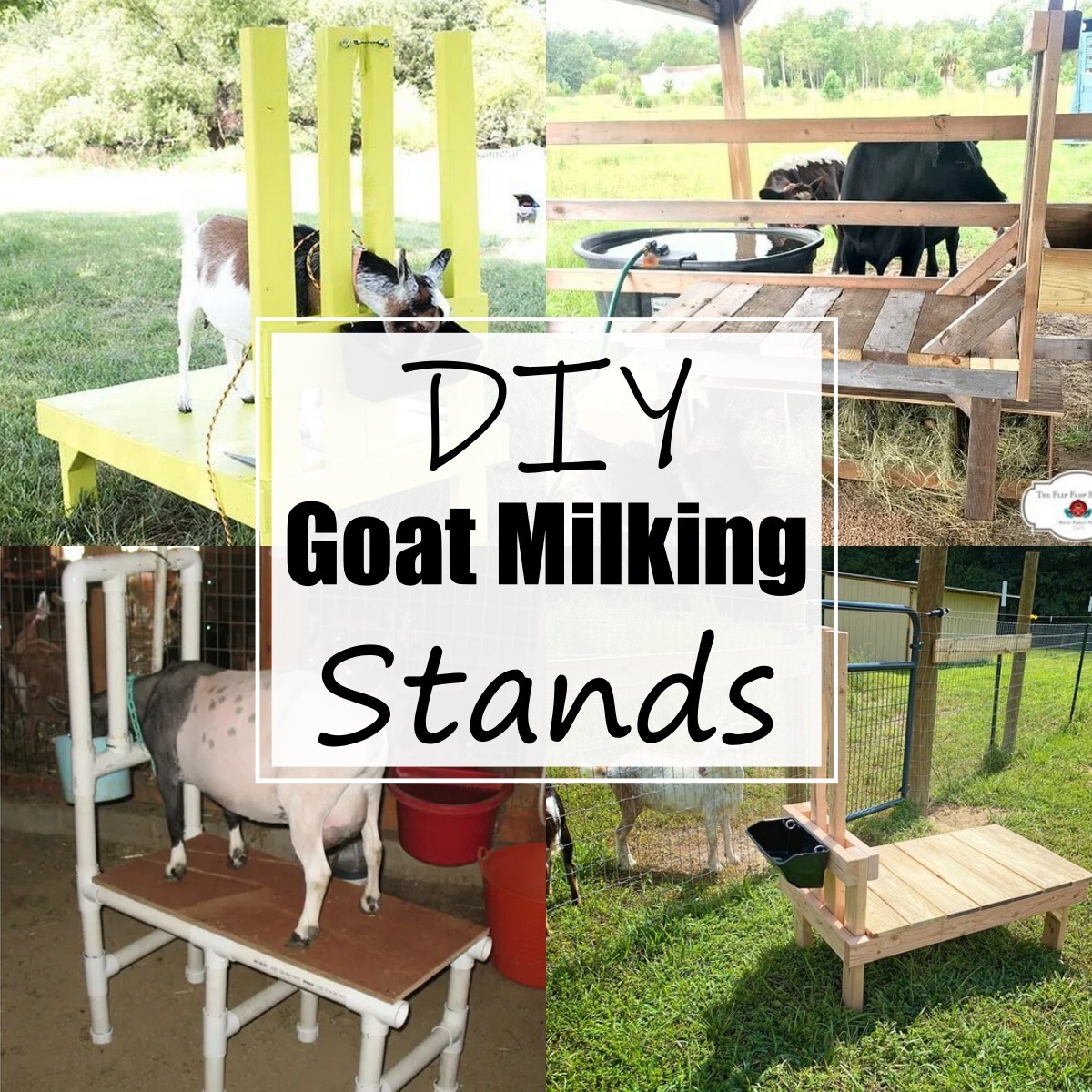

Types of Milking Stands

Various types of milking stands cater to different needs and preferences. Their designs vary significantly, offering diverse advantages and disadvantages. The selection of the appropriate stand depends on factors such as the size of the goat herd, available space, and the budget.

- Simple Elevated Platforms: These are often constructed from sturdy wood or metal and consist of a raised platform with a support structure. They are generally inexpensive and easy to construct, providing a basic elevation for milking. Their simplicity may, however, limit adjustability for different goat sizes and may not offer the same level of comfort or support compared to more complex designs.

A simple platform is ideal for small-scale operations with limited resources.

- Adjustable Stands: These stands incorporate mechanisms to adjust the height and angle of the platform. This adaptability accommodates goats of various sizes and body shapes, offering more comfort and reducing strain during milking. They typically require more complex construction and are often more expensive than simple platforms. These are beneficial for farms with a diverse herd size.

- Stanchion-style Stands: Stanchion stands are designed to secure the goat in a stationary position. These stands, often made of sturdy metal, feature a headrest and leg restraints, enabling a more controlled milking process. They offer improved safety for both the milker and the goat, but can be less adaptable to different goats’ sizes and may cause discomfort for some animals.

Design Examples and Functionalities

The design of a milking stand significantly influences its functionality and efficiency. Different designs cater to specific needs and preferences.

| Design | Functionality | Advantages | Disadvantages |

|---|---|---|---|

| Simple Elevated Platform | Basic elevation for milking. | Cost-effective, easy to construct. | Limited adjustability, potentially less comfortable. |

| Adjustable Stand with Adjustable Height | Allows for height adjustments to accommodate different goat sizes. | Enhanced comfort for the goat, accommodates various sizes. | Higher construction cost, more complex design. |

| Stanchion-style Stand | Secures the goat in a stationary position for controlled milking. | Improved safety, potentially faster milking. | Less adaptable to different goat sizes, potential for discomfort. |

Key Considerations When Choosing a Design

Several factors are crucial in selecting the appropriate milking stand design. The size of the goat herd, budget constraints, and the desired level of comfort and safety for the animals are critical considerations.

- Goat Size and Breed: Different breeds and sizes of goats may require different stand heights and support structures. Consider the average size of goats in the herd to ensure proper fit and comfort.

- Available Space: The dimensions of the available space will influence the design and size of the stand. A stand should fit comfortably within the available area, without compromising the goat’s freedom of movement or the milker’s accessibility.

- Budget: The cost of materials and labor will vary based on the chosen design. A budget should be established to guide the selection process.

- Safety and Stability: The stand must be sturdy and stable enough to prevent accidents during milking. Consider the potential weight of the goat and ensure the stand can support it safely.

Materials and Tools Needed

A well-constructed milking stand is crucial for efficient and safe goat milking. Careful selection of materials and tools is paramount to ensuring the stand’s longevity, stability, and overall usability. The right materials will contribute to a sturdy structure that can withstand the weight of the goat and the stress of regular use, while appropriate tools will facilitate the construction process effectively and safely.

Essential Materials

Choosing the right materials is vital for the milking stand’s structural integrity and longevity. The materials should be durable enough to withstand the weight and stress of a goat during milking. Proper selection ensures a safe and stable environment for both the goat and the milker.

- Wood (e.g., pressure-treated lumber): A sturdy wood is essential for the base, frame, and supporting structure. Pressure-treated lumber is recommended for its resistance to rot and decay, extending the stand’s lifespan. Dimensions for the base should be approximately 36 inches wide by 48 inches long, providing ample space for the goat to stand comfortably. The frame should consist of 2x4s or similar supports, depending on the intended weight and dimensions.

For example, 2x4s spaced approximately 12-18 inches apart for the frame are sufficient for most goats.

- Metal (e.g., sturdy angle iron or pipe): Metal components, such as angle iron or pipe, are beneficial for reinforcing the frame and creating a more robust structure. This is particularly important for areas that experience high stress. For instance, using angle iron for the corners of the frame and at points where the frame meets the base would significantly increase the stand’s stability. Metal should be chosen with a gauge appropriate to the expected weight.

- Hardware (e.g., screws, nails, bolts): High-quality fasteners are necessary for assembling the stand. Consider using galvanized screws or bolts for added rust resistance. The quantity of hardware will depend on the design and the size of the stand. A sufficient amount should be available for all connections, allowing for multiple backups. For example, use galvanized screws and bolts to ensure durability, preventing rusting, and maintaining stability over time.

- Optional Padding (e.g., rubber mats or plywood): Adding a layer of padding, such as rubber mats or plywood, beneath the goat’s feet will enhance comfort and prevent slipping, improving the goat’s experience. This is especially beneficial if the stand is to be used frequently or in uneven areas. An example could be using rubber mats or plywood under the base to cushion the goat and avoid injury.

The size of the padding should match the base’s dimensions.

Necessary Tools

A proper selection of tools is crucial for accurate and safe construction. Using the correct tools will not only ensure a well-constructed stand but also minimize the risk of injury.

- Measuring tape: Accurate measurements are vital for ensuring the stand’s dimensions are appropriate for the goat. For example, ensuring the width and length of the base are adequate for the goat’s comfort and preventing any stress.

- Saw (e.g., circular saw, hand saw): A saw is needed for cutting wood to the required dimensions. Choose a saw that is appropriate for the type of wood being used and the size of the cuts required. For instance, a circular saw is more efficient for large cuts, while a hand saw might be suitable for smaller cuts or intricate shapes.

- Drill and drill bits: Drilling holes for screws and bolts is a necessary step in assembling the stand. The appropriate drill bit size should be used to avoid damaging the wood. This ensures precise and safe assembly. For example, use a drill with appropriate bits to avoid wood splintering or damage during assembly.

- Hammer and nails (or equivalent fasteners): Fasteners are essential for securing various components of the stand. A hammer is used for driving nails or other fasteners into the wood. Using a hammer with the correct size and type of nail is important for ensuring the stand’s integrity.

- Safety glasses and gloves: Safety equipment is crucial to protect the builder from potential injuries during the construction process. For instance, wearing safety glasses protects the eyes from flying debris, and gloves prevent hand injuries during the sawing or hammering process.

Material Costs (Estimated)

| Material | Quantity | Estimated Cost per unit | Total Estimated Cost |

|---|---|---|---|

| Pressure-treated lumber (2×4) | 10 linear feet | $2.50/linear foot | $25.00 |

| Angle iron | 5 feet | $1.50/foot | $7.50 |

| Hardware (screws, bolts) | 100 | $0.05/piece | $5.00 |

| Rubber mats | 1 square foot | $1.00/square foot | $1.00 |

| Total | $38.50 |

Note: Prices may vary based on location and supplier.

Design and Construction of the Stand

A well-designed milking stand is crucial for both the comfort of the goat and the efficiency of the milking process. A sturdy, properly sized stand ensures the goat is positioned comfortably and safely during milking, reducing stress and promoting a positive experience. This section details the design and construction of a basic milking stand, outlining essential steps, safety considerations, and alternative designs.A stable and ergonomically sound milking stand promotes a comfortable experience for both the goat and the milker.

The stand should be easily adjustable to accommodate goats of varying sizes. Proper measurements and attention to structural integrity are paramount to ensuring the safety of the goat and the longevity of the stand.

Basic Design

This design utilizes readily available materials, focusing on stability and ease of use. The illustration depicts a simple A-frame structure with a platform for the goat. A crucial aspect of this design is the adjustable height feature. This accommodates different sized goats, ensuring a comfortable milking experience.

Materials and Tools

The materials required for construction include: two sturdy wooden beams, four wooden posts, metal brackets, screws, bolts, wood glue, and a level. Essential tools include a saw, drill, screwdriver, and measuring tape. The specific types of wood will depend on the desired durability and aesthetic.

Step-by-Step Construction

- Foundation and Base: Measure and mark the ground for the placement of the stand. Ensure the ground is level using a spirit level. Dig shallow holes for the wooden posts, ensuring the base is stable. Place the posts in the holes and secure them with concrete to prevent shifting. This creates a solid foundation for the rest of the structure.

- Frame Assembly: Cut the wooden beams to the desired length, ensuring accurate measurements to support the weight of the goat. Use metal brackets to securely attach the beams to the posts, ensuring a strong and stable frame. Use wood glue to enhance the structural integrity and ensure a secure bond.

- Platform Construction: Construct a sturdy platform from plywood or thick planks. Ensure the platform is wide enough to accommodate the goat’s body and is slightly sloped to allow for drainage. Attach the platform securely to the frame using appropriate hardware. This will prevent the platform from sagging under load.

- Finishing Touches: Apply a protective sealant or paint to the wood to prevent moisture damage and extend the lifespan of the stand. Ensure the stand is stable and level before use. This step ensures longevity and reduces the chance of accidents.

Safety Precautions

- Proper Ground Preparation: A level and stable foundation is crucial to prevent tipping and ensure the safety of the goat. Use appropriate leveling tools to ensure the ground is level.

- Secure Hardware: Use appropriate screws, bolts, and brackets to ensure all connections are strong and secure. Over-tightening can damage the wood. Ensure all hardware is appropriate for the material used.

- Structural Integrity: Regularly inspect the stand for any signs of damage or wear. Make necessary repairs to maintain its structural integrity. This proactive approach prevents accidents.

- Goat Comfort: Ensure the platform is comfortable and spacious for the goat. A smooth, non-slip surface is recommended.

Alternative Design Solutions

- Metal Frame Stand: Metal frames offer greater strength and durability compared to wood, especially in wet or humid environments. A metal stand is ideal for large-scale goat farms. However, the initial cost may be higher.

- Adjustable Height: A stand with adjustable height allows for accommodation of goats of varying sizes. This design ensures the comfort of all goats. Adjustable legs can be incorporated into the design to provide height adjustments.

- Portable Stand: A portable design allows for easy movement of the stand to different locations. This can be useful for farms with multiple milking areas or for seasonal needs.

Importance of Measurements and Structural Integrity

Accurate measurements and a strong structure are essential for the safety of the goat and the longevity of the stand. A well-constructed stand ensures the goat is positioned comfortably and securely during the milking process, minimizing stress and promoting a positive experience. Adequate support and stability are critical to prevent injury to the goat and damage to the stand itself.

Examples of poor structural integrity can lead to accidents and reduced productivity.

Dimensions and Measurements

A well-designed milking stand ensures both the goat’s comfort and the milker’s ease of access. Proper dimensions and measurements are crucial for achieving this balance. Careful consideration of these factors guarantees a stable, safe, and productive milking experience.Appropriate dimensions for the stand will depend on the size of the goat. Smaller breeds like Nigerian Dwarf goats will require a smaller footprint than larger breeds such as Nubians.

A customizable design is essential to accommodate the variety of goat sizes encountered. This section will Artikel the key dimensions and considerations for building a suitable milking stand.

Goat Breed Specific Dimensions

The milking stand’s dimensions should accommodate various goat breeds. Different breeds have different sizes, impacting the optimal height and width. A standardized design will not work for all breeds, hence the need for adaptable dimensions.

| Goat Breed | Height (inches) | Width (inches) | Length (inches) |

|---|---|---|---|

| Nigerian Dwarf | 30-36 | 24-30 | 36-42 |

| Nubian | 36-42 | 30-36 | 42-48 |

| Saanen | 42-48 | 36-42 | 48-54 |

| LaMancha | 33-39 | 27-33 | 39-45 |

This table provides a range of dimensions for different goat breeds. The specific measurements should be adjusted based on the individual goat’s size.

Optimal Height and Width

The optimal height for the milking stand is crucial for both the goat and the milker. A height that allows the goat to comfortably rest its front legs on the stand, and the milker to easily reach the udder without strain, is ideal. This ensures comfort and reduces the risk of injury for both parties. A height of 36-42 inches is commonly recommended for most breeds.

The width of the stand should allow the goat to comfortably stand without feeling cramped. This can vary depending on the goat’s size and the stand’s design. For most breeds, a width of 30-36 inches is suitable.

Support Structure Calculations

Calculating the support structures is vital for ensuring the stand’s stability. The weight of the goat and the equipment used for milking need to be considered. A simple formula for calculating the weight capacity is the following:

Weight Capacity = (Support Structure Strength) x (Safety Factor)

The support structure strength is determined by the material used (e.g., wood type, metal strength) and its dimensions. A safety factor of 2 is often recommended. This accounts for unexpected loads and ensures a margin of safety. Consider using sturdy materials like treated lumber or metal for the stand’s frame. The design should incorporate bracing and reinforcement to maximize stability.

Weight Capacity Measurement

Accurately measuring the weight capacity is essential for the stand’s safety. The stand must be able to support the weight of the goat and the milker without collapsing. The weight capacity should be calculated based on the anticipated maximum load. Consider the average weight of the goat breed and add a margin of safety.

Spacing Between Components

The spacing between components of the stand is essential for both functionality and safety. Adequate spacing allows for comfortable movement of both the goat and the milker. This includes the spacing between the supporting legs, the area for the goat to stand, and the area for the milker to work. Proper spacing also minimizes the risk of tripping or injury.

A rule of thumb is to maintain a minimum of 6 inches of space between the legs and the milking area.

Safety Considerations During Milking

Proper safety procedures are paramount during goat milking to ensure a comfortable experience for the animal and prevent injuries to both the goat and the milker. A well-designed milking stand, combined with careful handling techniques, minimizes risks and promotes a positive interaction between the goat and the milker.Maintaining a safe and stress-free environment for the goat is crucial for efficient and successful milking.

This includes minimizing the goat’s fear and anxiety, thereby encouraging cooperation and a positive association with milking. Safe practices also contribute to the goat’s overall well-being.

Importance of a Secure Milking Stand

A stable and sturdy milking stand is essential for preventing slips, falls, and injuries during the milking process. The stand should be constructed from strong materials and positioned on a level surface. Properly secured, it minimizes the risk of the goat or the milker losing their balance, which can lead to injuries.

Goat Handling Techniques

Gentle and consistent handling during milking is vital to avoid startling or injuring the goat. Avoid sudden movements or loud noises. Gently restrain the goat using appropriate techniques. Gradually introduce the goat to the milking stand and the milking process to build trust and familiarity.

Minimizing Risks of Injury

Accidents during milking can be avoided through proactive measures. Proper lighting, a well-organized work area, and the use of appropriate tools reduce the risk of slips, trips, and falls. Ensuring the goat is properly restrained on the stand minimizes the risk of the goat kicking or moving suddenly. A keen eye for potential hazards and swift reactions to any signs of discomfort are vital.

Essential Safety Equipment

A comprehensive list of safety equipment ensures a safe and efficient milking experience.

- Restraint Equipment: A properly fitted halter, lead rope, or similar restraint is essential to secure the goat safely during milking. Ensure the restraint is comfortable and doesn’t restrict the goat’s breathing or movement unnecessarily. Examples include padded halters and gentle lead ropes.

- Protective Gear: Gloves, sturdy footwear, and long sleeves can protect the milker from injuries caused by the goat’s hooves, horns, or accidental contact with the goat. Wear gloves to prevent cuts or abrasions during handling.

- Illumination: Adequate lighting is critical, particularly in poorly lit areas. Ensure sufficient light around the milking area to prevent accidents and allow for clear visibility of the goat and the milking process. Use lamps or strategically positioned lights.

- First Aid Kit: A readily accessible first aid kit should be available to address minor cuts, scrapes, or other injuries. Include bandages, antiseptic wipes, and pain relievers. Have gauze and tape to manage minor injuries.

- Appropriate Milking Tools: Using properly maintained milking equipment, including buckets and teat cups, minimizes the risk of injury to the goat’s teats. Ensure the milking equipment is clean and sanitized to avoid infection.

Maintaining a Comfortable Environment

A comfortable environment promotes cooperation and reduces stress during the milking process. Maintaining a clean and well-ventilated milking area helps to keep the goat calm and healthy. Providing a gentle background noise can minimize the goat’s anxiety. A warm, well-lit, and odor-free space will keep the goat relaxed and comfortable.

Proper Milking Technique

Correct milking technique ensures the comfort and health of the goat. Avoid pulling or twisting the teats. Always maintain a gentle and consistent pressure to minimize discomfort. Use proper milking equipment, ensuring it’s clean and correctly applied to the teats.

Maintenance and Care

Proper maintenance of a goat milking stand is crucial for its longevity and for ensuring a safe and hygienic milking environment. Regular care prevents wear and tear, reduces the risk of injuries, and promotes optimal sanitation. This section details the essential steps for maintaining your milking stand.Maintaining a clean and well-maintained milking stand is vital for the health and comfort of your goats.

A clean environment reduces the risk of bacterial contamination, preventing potential health issues for your animals. Regular inspection and upkeep will ensure the stand’s structural integrity, safeguarding the safety of both you and your goats.

Importance of Regular Maintenance

Regular maintenance tasks, such as cleaning and lubrication, extend the life of the milking stand and prevent costly repairs. Addressing minor issues promptly avoids escalating problems and potential accidents. This proactive approach ensures a smooth and safe milking process.

Cleaning and Disinfecting Methods

Thorough cleaning and disinfection are essential for preventing the buildup of bacteria and pathogens. Cleaning removes visible dirt and debris, while disinfection kills microorganisms. This dual approach safeguards the health of your goats and minimizes the risk of infections.

- Cleaning: Use warm soapy water to remove accumulated dirt, debris, and milk residue. Scrub all surfaces thoroughly, paying particular attention to crevices and corners. Rinse thoroughly with clean water to eliminate all traces of soap.

- Disinfecting: After cleaning, apply a suitable disinfectant solution, following the manufacturer’s instructions. Allow the disinfectant to remain on the surfaces for the recommended contact time. Ensure thorough rinsing to eliminate any residual disinfectant.

Identifying and Addressing Potential Issues

Regular inspection allows for early detection of potential issues, such as loose bolts, damaged parts, or signs of wear. Addressing these issues promptly prevents more significant problems and ensures the stand’s structural integrity.

- Loose Bolts: Periodically check all bolts and fasteners for tightness. Tighten any loose bolts to prevent slippage and ensure stability.

- Damaged Parts: Inspect all components for any signs of damage, such as cracks, dents, or corrosion. Replace damaged parts immediately to maintain structural integrity and prevent accidents.

- Signs of Wear: Observe the stand for any signs of wear, such as excessive rust or bending in metal parts. Consider replacement or repair if necessary.

Examples of Common Maintenance Tasks

These examples highlight common tasks for maintaining your milking stand:

- Lubrication: Regularly lubricate moving parts, such as hinges and rollers, with appropriate lubricant to ensure smooth operation and prevent friction.

- Rust Prevention: Apply a protective coating, such as paint or rust inhibitor, to metal parts to prevent rust formation. This is especially important in humid environments.

- Checking for Stability: Ensure the stand is stable and level. Adjust the stand’s position if needed to prevent tilting or wobbling during milking.

Preventative Maintenance Schedule

A preventative maintenance schedule helps maintain the milking stand in optimal condition.

| Frequency | Tasks |

|---|---|

| Weekly | Cleaning and disinfection of all surfaces; checking for loose bolts and fasteners. |

| Monthly | Lubricating moving parts; inspecting for signs of wear and tear. |

| Quarterly | Thorough cleaning and disinfection of all surfaces; checking structural integrity; assessing stability. |

Alternative Design Ideas

This section explores various design alternatives for a simple goat milking stand, considering different materials and their respective advantages and disadvantages. Understanding these options will empower you to choose the best fit for your specific needs and resources.

Alternative Designs for Goat Milking Stands

Different designs offer varying degrees of stability, accessibility, and ease of use. Careful consideration of the design is crucial for the comfort of both the goat and the milker. The chosen design should prioritize safety and efficiency throughout the milking process.

| Design | Materials | Pros | Cons | Assembly Steps |

|---|---|---|---|---|

| A-Frame Stand | Wood (treated lumber), Metal pipes (galvanized or stainless steel) | Relatively easy to construct, provides good stability, adaptable to various goat sizes, aesthetically pleasing. | Can be more challenging to assemble compared to a simple platform, may require more tools for construction. | 1. Cut lumber to desired length for the A-frame. 2. Securely fasten the frame using screws or bolts. 3. Install a sturdy platform for the goat to stand on. 4. Ensure the platform height and angle provide comfortable access for milking. |

| Elevated Platform Stand | Wood (treated lumber), Metal (galvanized or stainless steel), concrete | Provides good accessibility for the milker, enhances comfort for the goat, relatively easy to construct. | May require more materials for a stable platform, height adjustment can be tricky. | 1. Prepare a level base for the platform. 2. Construct the elevated platform using the chosen material. 3. Ensure the platform height is appropriate for milking. 4. Install sturdy support legs. |

| U-Shaped Stand | Metal (galvanized or stainless steel), Reinforced wood | Provides excellent support for the goat, allows for easy access from multiple sides, reduces stress on the goat’s back. | More complex to construct, potentially higher cost compared to simpler designs. | 1. Create the U-shape frame using the selected material. 2. Attach a sturdy platform to the frame, ensuring even weight distribution. 3. Adjust the platform height for proper milking positioning. 4. Reinforce the structure for added stability. |

| Simple Platform Stand | Wood (treated lumber), Metal (galvanized or stainless steel) | Simplest design, relatively inexpensive, easy to assemble. | May require more support to maintain stability for larger goats, may not be as comfortable for the goat as other designs. | 1. Construct a flat platform using the selected material. 2. Secure the platform to the ground or legs using appropriate fasteners. 3. Ensure the platform height is appropriate for milking. |

Material Considerations for Milking Stands

Selecting the right material for your milking stand is crucial for its durability and longevity. The choice depends on factors such as cost, availability, and the desired level of stability.

- Wood (treated lumber): A readily available and affordable option, but susceptible to weathering and requires regular maintenance. Pressure-treated lumber is resistant to rot and decay, extending the lifespan of the stand. Example: Pressure-treated pine or redwood for durability and longevity.

- Metal (galvanized or stainless steel): Provides exceptional durability and resistance to rust and corrosion. However, it may be more expensive than wood. Example: Galvanized steel for a robust and long-lasting stand, or stainless steel for superior hygiene.

- Concrete: Provides maximum stability and longevity. Ideal for permanent installations, but the construction process is more complex. Example: Concrete platforms offer unparalleled stability for a long-term investment.

Assembly Procedures for Each Design

The assembly procedures for each design vary depending on the complexity of the stand. Detailed instructions are provided for each type to ensure proper construction and safety. Carefully follow each step to achieve a sturdy and safe milking stand.

Goat Breeds and Stand Adaptations

A well-designed milking stand should accommodate the diverse needs of various goat breeds, ensuring both comfort for the animal and ease of milking for the farmer. Factors such as breed-specific size, weight, and body conformation play a crucial role in stand design to prevent discomfort and injury during the milking process.Understanding the variations in goat breeds allows for tailored stand designs, enhancing the overall milking experience for both the goat and the milker.

This section details how to adapt the stand’s design to accommodate different goat breeds.

Size and Weight Considerations for Different Goat Breeds

Different goat breeds exhibit significant variations in size and weight. A stand designed for a small pygmy goat will likely be inadequate for a large Alpine or Boer goat. Consideration of weight capacity is paramount to ensure the stand’s structural integrity and safety for the animal.

- Small breeds, like pygmy goats, require a smaller, lighter stand. A stand designed for larger breeds should be robust enough to support the weight.

- Larger breeds, such as Nubians or Boer goats, need a stand with a wider base and stronger supports to prevent tipping or wobbling. The stand should be able to bear their weight and prevent discomfort during milking.

Stand Height Adaptations for Different Breeds

Stand height is critical for both comfort and accessibility. A stand that is too high or too low can cause strain on the goat’s back or make it difficult for the milker to reach the udder.

- Different breeds have varying body heights. A stand that is appropriate for a smaller breed like the La Mancha will not be suitable for a larger breed like a Toggenburg. The stand should be adjusted to a height that allows the milker to comfortably reach the udder.

- Height adjustments should be easily accomplished, allowing for flexibility in accommodating goats of various sizes.

Stand Width and Support Adaptations

The width of the stand should consider the goat’s body conformation and udder size. A wider stand provides more support, particularly for larger breeds or goats with larger udders.

- Wide stands provide more stability for larger breeds, preventing the animal from shifting or falling. The stand’s width should allow the goat to comfortably stand without putting undue pressure on its legs.

- Ensure the stand’s supports are properly positioned and braced to prevent movement or tipping, even with a larger breed or a heavier goat.

Special Considerations for Specific Goat Breeds

Certain breeds might have unique needs or considerations. For example, goats with a shorter or longer body may need adjustments in stand design to prevent strain on their bodies.

- Breeds like the Alpine, known for their larger size, may require a wider and stronger stand with adjustable height features. This will accommodate the breed’s typical body size and weight.

- Specific breed characteristics, such as udder shape and size, should be considered during the design process to ensure a comfortable milking experience for each breed.

Illustrative Modifications for Different Goat Breeds

Different breeds necessitate stand modifications to accommodate their unique needs.

- For small breeds like Pygmy goats, a smaller, lighter stand with lower height adjustments would be ideal. This would allow for ease of movement and comfort for the goat.

- Larger breeds, such as Boer goats, would benefit from a wider stand base with sturdier supports, ensuring stability during milking. Adjustments to the height and width of the stand would provide comfort for the animal.

Cost-Effective Materials

A crucial aspect of building a milking stand for goats is selecting cost-effective materials. This allows you to construct a sturdy and functional stand without breaking the bank. Careful material selection and planning can significantly reduce the overall project cost.By prioritizing cost-effective materials, you can allocate more resources to other crucial aspects of goat care, such as feed or veterinary expenses.

This approach makes the project financially manageable and sustainable in the long run.

Identifying Cost-Effective Materials

Several readily available materials can be utilized to construct a sturdy and functional milking stand. Prioritizing materials that are readily accessible and affordable is crucial. The choice of material often hinges on local availability and pricing.

Comparing Costs of Different Materials

A comparative analysis of materials’ costs is essential for informed decision-making. Different materials have varying prices, depending on local market conditions and supplier availability. Consider the cost per unit, including any necessary preparation or treatment.

| Material | Approximate Cost (per unit) | Pros | Cons |

|---|---|---|---|

| Wood (treated lumber) | $10-$50 | Versatile, relatively strong, readily available. | Susceptible to rot and decay if not treated. |

| Metal (recycled steel/galvanized sheet) | $5-$25 | Durable, resistant to rot and weather. | May require welding or specialized cutting, potentially heavier. |

| Recycled pallets | $0-$10 (depending on condition) | Free or low cost, readily available, provides a solid base. | May require significant repair and reinforcement, not always structurally sound. |

| Concrete blocks | $2-$5 | Extremely durable, relatively inexpensive. | Labor-intensive, may require additional support or reinforcement for the desired height. |

Examples of Recycled or Repurposed Materials

Many materials can be repurposed or recycled to create a cost-effective milking stand. Examples include:

- Recycled pallets: These offer a solid foundation for the stand. They are often free or inexpensive, but may require significant reinforcement and repair.

- Scrap metal: Galvanized steel sheets, or even repurposed metal from other projects, can be used for components. Ensure that the metal is clean and free of rust. Metal may require welding or specialized cutting.

- Old furniture or lumber: If you have access to scrap wood or furniture parts, these can be used to create the structure. Ensure the wood is treated to prevent rot.

Selecting Cost-Effective Materials

Careful consideration of several factors is crucial when selecting cost-effective materials. This involves assessing the availability, durability, and suitability of various materials.

- Local availability: Look for materials readily available in your area. This can often lead to significant cost savings.

- Durability: Select materials that can withstand the intended use and environmental conditions.

- Cost-benefit analysis: Compare the cost of different materials to their durability and overall value.

- Potential for recycling or repurposing: Explore the possibility of using recycled or repurposed materials. This is an environmentally friendly approach, often reducing costs.

Tips for Reducing Overall Construction Cost

Several strategies can help minimize the overall construction cost.

- DIY approach: Building the stand yourself can save on labor costs.

- Negotiate prices: Negotiate with suppliers for bulk purchases or discounts.

- Seek free or low-cost materials: Look for scrap materials, recycled materials, or freebies from friends, family, or local businesses.

- Prioritize functionality over aesthetics: Focus on creating a stand that meets your needs, not one that meets specific design criteria.

Environmental Impact

Choosing materials for a goat milking stand involves more than just practicality; it also necessitates considering the environmental footprint. A conscious approach to material selection can minimize the impact on the planet and promote sustainable practices. This section explores the environmental impact of various materials, suggests eco-friendly alternatives, and highlights sustainable construction methods.Responsible material selection and waste disposal are crucial steps in minimizing the environmental impact of building a milking stand.

This section will Artikel the considerations to take into account.

Material Selection and Environmental Footprint

Various materials have different environmental impacts, from the extraction of raw materials to manufacturing and disposal. Understanding these impacts is essential for making informed choices.

- Wood: Wood, a renewable resource, generally has a lower environmental impact than many other materials. However, the source of the wood, the harvesting practices, and the treatment methods (if any) play a role. Sustainable forestry practices, like reforestation and responsible logging, are key to minimizing the environmental footprint of wood. Examples include sustainably harvested hardwoods like oak or sustainably harvested softwoods like pine.

Using treated lumber may introduce chemical concerns, so using untreated wood when possible is a better choice.

- Metal (e.g., steel, aluminum): Metal production often involves energy-intensive processes and can generate significant emissions. Recycling metal significantly reduces the environmental impact. Steel, for example, is a readily recyclable material, which can greatly reduce its environmental impact compared to producing new steel. Aluminum, while lightweight and strong, has a higher energy consumption during production. Prioritizing recycled metal is a significant step toward a more sustainable approach.

- Concrete: Concrete production requires significant energy and resources. The cement component, a crucial ingredient in concrete, releases carbon dioxide during its production. Minimizing concrete usage or opting for alternatives like recycled concrete aggregates can be beneficial. Using concrete sparingly and focusing on recycled or low-carbon concrete alternatives can help mitigate the environmental impact.

Eco-Friendly Material Options

Several eco-friendly materials can reduce the environmental footprint of the milking stand’s construction.

- Recycled Materials: Utilizing recycled materials like scrap metal, reclaimed lumber, or recycled plastic significantly reduces the demand for virgin materials and decreases the environmental impact associated with waste disposal. Using recycled materials is a straightforward way to build a more sustainable milking stand.

- Bamboo: Bamboo is a rapidly renewable resource, requiring less land and water than many other timber sources. Bamboo is an excellent alternative for construction materials.

- Locally Sourced Materials: Using locally sourced materials minimizes transportation distances, reducing fuel consumption and associated emissions. This also supports local economies and reduces the environmental burden of long-distance transportation.

Sustainable Construction Practices

Implementing sustainable practices throughout the construction process can significantly minimize the environmental impact.

- Waste Reduction: Minimizing waste generation during construction through careful planning, accurate material estimations, and proper cutting techniques can dramatically reduce the environmental impact of the construction process.

- Water Conservation: Properly managing water usage during the construction process can minimize the environmental impact. Using water-efficient tools and techniques can conserve resources.

- Energy Efficiency: Utilizing energy-efficient tools and equipment can reduce the energy consumption required for construction. Choosing electric tools over gas-powered ones is a good practice.

Responsible Waste Disposal

Proper waste disposal is essential to minimize environmental damage.

- Recycling and Composting: Separating recyclable materials (metal, wood, plastic) from non-recyclable waste allows for proper recycling and composting, reducing landfill waste. This helps in minimizing the environmental impact associated with waste disposal.

- Landfill Minimization: Planning construction to minimize waste is crucial. Accurate material estimation and careful cutting techniques are essential steps in this regard.

Troubleshooting Guide

A well-constructed milking stand can significantly improve the efficiency and safety of the milking process. However, like any piece of equipment, occasional issues may arise. A proactive approach to troubleshooting these problems can minimize disruptions and ensure a smooth milking experience. This section details common issues and their solutions.

Common Milking Stand Problems

Addressing potential problems early on can save time and frustration. A well-maintained milking stand, in combination with proper milking techniques, minimizes the likelihood of problems arising.

Instability and Uneven Support

Improper assembly or inadequate base support can lead to an unstable milking stand. If the stand wobbles or shifts during use, it is crucial to re-evaluate the assembly. Ensure all bolts and connections are tightened securely. Check if the stand’s base is level and stable on the ground. Adding additional leveling blocks or stabilizing materials under the base can prevent shifting.

Material Degradation

Over time, the materials used in the construction of the milking stand may experience wear and tear, particularly in outdoor settings. Signs of degradation, such as cracks, splintering, or rust, should be addressed promptly. Replacing damaged components with high-quality replacements is essential for maintaining the stand’s structural integrity. Regular inspections can help detect issues early.

Issues with the Milking System

Problems with the milking system itself can affect the milking process. For example, leaks in the tubing or inadequate suction can lead to difficulties in milk collection. Inspect the milking system for leaks and ensure that the suction is correctly adjusted. Consult the milking system manufacturer’s guidelines for specific troubleshooting steps.

Frequently Asked Questions

- What should I do if the milking stand is unstable? Ensure the stand is level and that all bolts and connections are secure. If necessary, add stabilizing materials to the base. If the issue persists, review the assembly instructions.

- How can I prevent material degradation? Protect the stand from harsh weather conditions by storing it indoors when not in use. Use appropriate coatings or treatments to prevent rust and decay. Regular inspections can detect problems early.

- What are the signs of a problem with the milking system? Look for leaks in the tubing, inadequate suction, or unusual noises during the milking process. If problems persist, consult the milking system manufacturer’s guidelines.

- How can I prevent future problems? Regularly inspect the milking stand for signs of wear and tear. Ensure proper maintenance procedures are followed. Maintain the milking system according to the manufacturer’s instructions.

Summary

In conclusion, constructing a simple milking stand for goats requires careful consideration of design, materials, and safety. This guide provides a framework for building a stand that prioritizes both the comfort and well-being of your goats and the efficiency of the milking process. Remember to prioritize safety throughout the construction and use phases. By following the detailed steps Artikeld, you can create a functional and sustainable milking stand for years to come.

Further, the cost-effective and environmentally conscious options explored in this guide provide a framework for a responsible and practical approach.